news

Unearthing Innovation: Shaping the Future with Circular Mining and Metals

Want to know the secret ingredient to unlocking long-term value of mining and resource recovery?

The answer is circularity, or, circular mining and metals.

Traditionally, circularity is described as an approach to eliminate waste and pollution by creating value from processes that would otherwise be considered wasteful. When we talk about circularity in the context of durable and valuable resources such as mineral and metals, circularity is simply the core strategy to create long-term and increasing value that delivers to climate, nature, and social ambitions.

With this in mind, Vale Base Metals has partnered with NineSigma to launch the Pyrrhotite Resource Recovery Innovation Challenge on March 4th, 2024, to seek sustainable and financially viable solutions from innovators from around the world to recover the valuable metals and minerals contained in pyrrhotite tailings.

Vale has chosen Open Innovation approach because it promotes transparency and accountability, driving progress towards a sustainable future in circular mining and metals. By teaming up with NineSigma, Vale is opening the doors to a diverse community of innovators worldwide, united in the quest to forge a more sustainable future through circular resource recovery.

Understanding Circularity

To better understand the concept of circularity as it relates to this challenge and the future of mining, we sat down with Christian Spano, Director of Circularity at Vale Base Metals.

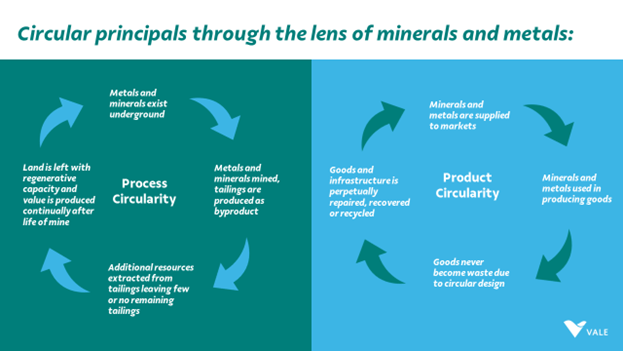

Circularity calls for a shift from traditional mining practices – where resources are extracted from the ground, consumed, and disposed of – to a more holistic approach. This new approach looks to frame the land where mineral deposits are present as regenerative sources of wealth, and considers value chains as stocks of resources that can be permanently repurposed, recovered, and recycled.

Circularity suggests that consumable goods, which create environmental impacts, such as food, oil & gas, and single-use plastics, must be either substituted or eliminated. Conversely, mineral and metals are different as these are durables that can be recovered indefinitely. Chris adds, “With mineral and metals we need to think about stocks of value and consider how to we can use them forever through circular strategies.”

“It’s almost like they are renewal resources,” says Chris. “The circular strategy for durables seeks to create an additional resource endowment by looking for ways to reuse the materials, forever.”

Through the lens of circularity, organizations consider mined minerals and metals to be assets that can be used and reused continuously, rather than as consumables which are designed to become waste and are liabilities.

Process Circularity aims to maintain the regenerative capacity, productivity, and value of the land throughout and beyond the mine’s lifecycle.

“The land we operate on is a natural endowment,” Chris says. “There is value in the water, land, and waste even after the minerals and metals are extracted from the ground. We need to work through innovation and partnerships to ensure that we can not only recover that value, but also find the market for it.”

Process circularity is critical to accelerate action to reduce emissions and deliver nature positive outcomes. Circularity focuses on recovering valuable materials from goods. “For instance,” Chris says. “We’re working hard to ‘close the loop’ at Vale Base Metals by collaborating with partners to recycle materials from existing electric batteries. Basically, our product is finding its way back to us which will allow us to supply critical energy transition materials beyond life of mine.”

Instead of treating tailings as waste, circular mining and metals initiatives, like the Pyrrhotite Resource Recovery Innovation Challenge, aim to frame tailings as new resource endowments rather than waste, seeking to extract value from them, maximizing resource utilization and minimizing environmental impact.

Why Is This Important?

The Pyrrhotite Resource Recovery Innovation Challenge presents a significant opportunity for both Vale Base Metals and the larger mining industry. By seeking novel approaches for resource recovery and waste management, the challenge has the potential to set new standards for resource recovery and sustainability.

“This challenge could come across as a ‘nice to have’, but it is much bigger than that,” Chris says “It is evidence that Vale Base Metals is differentiating itself from a traditional mining company. We are working to create a new culture and it shows who we want to be as a leading energy transition materials provider. The waste narrative limits us. We are embracing a regenerative resource culture, where we should exist to drive regeneration at site level and supply materials that can be recovered forever in a way that outcompetes the current model.”

An undertaking of this magnitude will not come easy and will require new technologies and partnerships.

“We will be transparent when we are struggling to find solutions. We will not fail, we will learn. That’s what this challenge is all about,” Chris says.

“We don’t have all the answers. We’re keen to hear from those who can help us, and we have a lot to offer too.”

“Not only do we have large pool of energy transition resources and infrastructure, but most importantly we have a wealth of knowledge and experiences,” he adds.

The mining industry is constantly changing. Climate change is one of the most pressing issues facing the world today, and the industry has intensified its commitment to sustainable practices. As climate change persists, the demand for sustainably sourced product will rise, offering substantial opportunities for organizations who embrace circularity principles.

The Future of Mining

In Chris’ vision for the future of mining, the industry will treat these metals and minerals as durables rather than consumables.

“We need to treat the natural endowments as precious resources that are regenerative,” said Chris. “As an industry, we can no longer just be extractive.”

This future may seem far away, but Chris remains optimistic.

“I have seen massive change during my time living in Peru, not only in the mining industry, but in the energy industry as well,” Chris says. “These experiences have shown me that the industry IS capable of change. By adopting circularity, we can create a more dynamic and economically attractive industry, where the value of resources is not limited to disposable materials or a single source of supply.”

Let’s Transform the Future Together!

For individuals, group, and organizations interested in Pyrrhotite Resource Recovery Innovation Challenge, Chris offers the following advice.

“The future has already started. Vale Base Metals is taking off and I encourage you to get on the spaceship. The work we do will be exciting and unforgettable as we will be changing the lives and transforming the future for generations to come.”

Roha Ali Khan, who is managing the Pyrrhotite Resource Recovery Innovation Challenge from NineSigma’s side, echoes Chris’s sentiment, emphasizing the transformative potential of joint collaboration and open innovation. “The future has already begun,” she affirms. “By leveraging NineSigma’s experience, we ensure a fully transparent process that fosters trust and inclusivity. For those interested in participating, now is the time to join us on this journey. Together, we can embark on an exciting adventure, changing lives and transforming the future for generations to come.”

Stay Connected

If you are interested in building a cleaner, greener, and more prosperous future, submit your proposal for The Pyrrhotite Resource Recovery Open Innovation Challenge. Please be advised, the Vale Base Metals’ team is only accepting proposals until May 31st, 2024.

To learn more about the Pyrrhotite Resource Recovery Open Innovation Challenge, visit the challenge page.

For updates on the challenge, be sure to follow Vale Base Metals & Ninesigma on LinkedIn!

Other topics :

Get in touch

NineSigma Europe BV

Koning Leopold I straat 3B-3000 LeuvenBelgium

+32 16 24 42 80

europe@ninesigma.com

NEWS